P +48 888 777 277

Visit our store for more great products including Berger bullets - Spuhr - Target Vision - Turban presses and more... Click here

GREAT PRODUCTS FROM PRO-SHOOTING

MagnetoSpeed Chronographs

Whidden Reloading Dies

MARCH Scopes - Full range

Products

About Us

Contact Us

English

Polish

– Recent Projects –

Redding Reloading Range

Since 1946 Redding has provided the reloading marketplace with innovative, American Made products of the highest quality.

Redding Reloading Equipment

Redding are not just a small piece of a large corporation, so they are committed to producing the best possible products. Over the past five years they purchased and installed in 12 new pieces of American Made CNC Machinery to keep pace with rising market demand. In that same period, Redding completed a major facility expansion allowing them to increase our warehousing and distribution operations to keep pace with today's growing reloading market. It has also allowed Redding to add even more new CNC Machining Centres, thereby further increasing Redding’s commitment to their growing group of loyal customers throughout the USA and around the world.

Download the latest Redding Catalogue.

This contains all the information and sizes/calibre options etc for all products list here on Pro-Shooter.

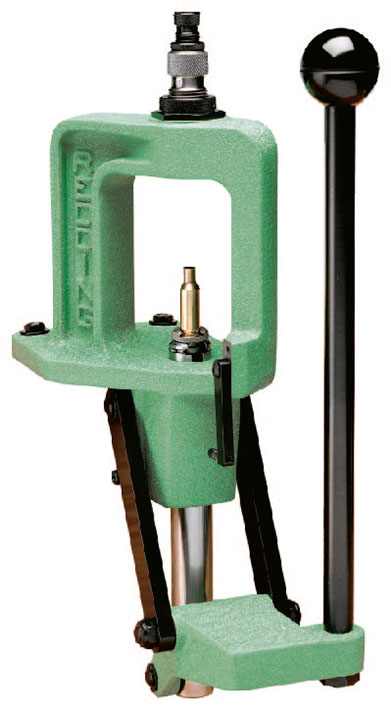

The Boss Reloading Press

Here is the press that has all the features reloader’s look for. It’s cast iron construction insures that it will last a lifetime, yet it is priced with light-duty aluminium presses! The BOSS is powerful, remarkably easy to use, and yet sensitive enough to seat primers without crushing them.

Take a look at all the features The BOSS offers and you’ll be convinced…when it comes to “O” Type reloading presses, this one is truly a smart choice.

Features

Rigid cast iron frame

36˚ frame offset gives

the best visibility

and access of all

comparable presses

“Smart” primer arm automatically moves in and out of position with ram travel. Priming arm is positioned where it should be…at the bottom of ram travel for the lowest leverage and best feel

Offset handle is in the most comfortable operating position yet out of the way for best access and visibility

Positive ram travel stop

Powerful compound linkage

3 holes for rigid mounting

Accepts all standard 7/8"-14 threaded dies and universal shell-holders

Shell holders may be rotated to any comfortable position desired

Includes primer catcher

The Big Boss II

Now featuring the unique Redding Spent Primer Collection System” used on the T-7 and Ultramag presses.

These top of the line single station presses have the largest window opening and longest usable ram stroke of any in their class.

Both the original Big Boss and the new Big Boss II reloading presses have all the desirable features of the Boss” reloading press, but are built on heavier frames with a 1” diameter ram and longer 3.8” usable ram stroke for reloading the largest magnum cartridges.

The Big Boss II now features the unique Redding Spent Primer Collection System” used on the T-7 and Ultramag presses. This top of the line single station press has the largest window open-ing and longest usable ram stroke of any press in its class. Simply, the only press you will ever need!

Features

Spent primer

collection system

1” diameter ram

Heavy duty cast

iron frame with

36° offset for easy

access and visibility

Large 4-1/2" frame

opening

3-13/16" of ram stroke for easy reloading of magnum cartridges

Offset/straight pull ball handle for ease of operation

Smart" primer arm that moves in and out of position with ram travel

Heavy duty compound linkage

Steel adapter bushing accepts all standard 7/8"-14 threaded dies and is removable for use with oversized dies

Frame with bushing removed accepts 1-1/4" - 12 dies

PRO PACK Reloading KIT

We’ve selected our best reloading com-ponents and put them into one neat, money-saving package. This kit was created for both the first-time reloader to get started right and for the more advanced reloader desiring to upgrade his equipment.

The Boss and Big Boss Pro-Pak contain the following:

The Boss or Big Boss Reloading Press – Our best selling presses.

Model 2 Powder and Bullet Scale. Simply the most sensitive, most accurate scale on the market.

Powder Trickler – Heavy stable companion to the powder scale.

Pad Style Case Lube Kit – Consists of our non-skid lube pad and our Imperial Bio-Green case lube.

Deburring Tool – The cutting edges are ground correctly for clean chatterless cuts.

Model 18 Case Preparation Kit –Plastic accessory handle with all the tools and brushes you need to properly clean your fired cases before resizing.

Powder Funnel – Made of tough Lexan® and nearly indestructible.

Hodgdon Annual Manual –Reloading information for rifle and pistol ammo using Hodgdon, IMR & W-W powders in addition to a variety of helpful handloading articles

The Ultramag Reloading Press

At first glance you will see what sets the ULTRAMAG apart from all other reloading presses: the unique location of its compound leverage system. Unlike other reloading presses which connect the linkage to the lower half of the press, the ULTRAMAG’S leverage system is connected to the top of the press frame. This allows you to develop literally tons of pres-sure without the usual concern about press frame deflection or misalignment.

The ULTRAMAG features a huge 4-3/4” frame opening and 4-1/8” of usable ram stroke, making it ideal for loading over-sized cartridges such as the old Sharps “Buffalo Cartridges” and British “Nitro-Express” rounds.

Its unique long link compound leverage system has more mechanical advantage over a greater distance than any other reloading press on the market. This makes “childs play” of difficult case forming operations.

“The largest and strongest press available for the toughest reloading chores…”

HANDLOADER Magazine, No. 148

Features

The frame is constructed of high grade cast iron for strength, long life and wear resistance

Four mounting holes provide rigid mounting

Offset handle is out of the way for all reloading operations

All linkage pins are heat treated, precision ground and in double shear

Steel adapter bushing accepts standard 7/8"-14 threaded dies and is removable for use with oversized dies

Frame with bushing removed accepts 1-1/4" - 12 die threads

Smart primer arm that moves in and out of position with ram travel

Spent primer collection system

The T-7 Turret Reloading Press

The T-7 combines strength, power and convenience with the speed and versatility of a turret press.

The design criteria was to create the ultimate turret press. Our engineering team started with our time proven cast iron construction and turret support that is second to none. They added powerful compound linkage with over 3.8” of ram travel. A 1” diameter hollow ram was chosen with the “smart primer arm” and “spent primer collection system” borrowed from our Ultra Mag. Another station was added to the turret for even greater versatility and an optional “Slide Bar Automatic Primer Feeding System” was designed.

After adding a few more subtle refinements and built with the precision you would expect from Redding, we’re confident this is the best turret press ever.

Shown with optional “Slide Bar Automatic Primer Feeder System”. Also fits the new Big Boss Press.

Cast iron construction, powerful compound linkage and a rigid seven station turret combine to make the

Redding T-7 the best turret press ever...

Features

Seven station turret head with operating handle

Heavy duty cast iron frame for strength and wear resistance

Powerful compound linkage with positive ram stop.

1” diameter ram

4-3/4” press opening

3-13/16” ram stroke

Ball handle

Spent primer collection system

Accepts all standard 7/8"-14 threaded dies and universal shell holders

Shell holders may be rotated to any comfortable position desired

Smart primer arm for seating small and large primers

Interchangeable turret heads

Competition die compatible

SAECO Lubri-Sizer

Considered by many to be the finest lubricator/sizer available today. A single stroke seats gas checks, swages bullets to proper diameter, and lubricates them. The pressurised reservoir lubricates from 20 to 50 bullets between turns of the lube control handle. Parallel guide rods assure proper alignment of the top punch and sizing die, resulting in maximum bullet concentricity.

Those who prefer to shoot bullets “as cast” will appreciate the exclusive swing out gas check seater which allows the option of seating gas checks without sizing.

A combination of compound leverage and extra length operating handle substantially reduces physical effort. Sizing Dies and Top Punches are not included and should be ordered according to caliber and bullet design.

SAECO – a product of Redding Since 1985

SAECO Sizing Dies

SAECO sizing dies are made with a unique pre-lead that

fits the “as cast” bullet diameter. This insures that bullets

feed into the sizing diameter in absolute straight alignment.

The dies are finished by internal honing known as micro-finishing which produces a mirror finish and a sizing hole that is perfectly round. Your bullets will look like polished silver with no lead shavings.

SAECO – a product of Redding Since 1985

® Pro Shooting // All Rights Reserved. Website Design - EDGE