P +48 888 777 277

Visit our store for more great products including Berger bullets - Spuhr - Target Vision - Turban presses and more... Click here

GREAT PRODUCTS FROM PRO-SHOOTING

MagnetoSpeed Chronographs

Whidden Reloading Dies

MARCH Scopes - Full range

Products

About Us

Contact Us

English

Polish

– Recent Projects –

Redding Reloading Range

Since 1946 Redding has provided the reloading marketplace with innovative, American Made products of the highest quality.

Redding Reloading Equipment

Redding are not just a small piece of a large corporation, so they are committed to producing the best possible products. Over the past five years they purchased and installed in 12 new pieces of American Made CNC Machinery to keep pace with rising market demand. In that same period, Redding completed a major facility expansion allowing them to increase our warehousing and distribution operations to keep pace with today's growing reloading market. It has also allowed Redding to add even more new CNC Machining Centres, thereby further increasing Redding’s commitment to their growing group of loyal customers throughout the USA and around the world.

Download the latest Redding Catalogue.

This contains all the information and sizes/calibre options etc for all products list here on Pro-Shooter.

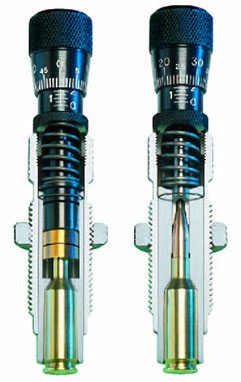

Competition Bullet Seating Die

No seating die on the market is built to this level of precision…

Alignment and accuracy are enhanced by the cartridge case and bullet being completely supported and aligned in a close fitting, precision ground sleeve before the bullet seating begins.

The micrometer is calibrated in .001" increments for precise seating depth and is infinitely adjustable. The micrometer also has a feature that allows you to re-set it to your favourite seating depth.

No seating die on the market is built to this level of precision.

This patented design quickly established itself as the “state of the art” in straight line bullet seaters and beat the concentricity problems inherent in all other seating dies of this type.

Tighter manufacturing tolerances were made possible due to the details of the floating seating stem system. The bullet guide to seating stem fit is so precise that the seating stem can actually be demonstrated to “float” on a column of air. The seating stem is precision ground to exactly match the bullet diameter.

The Redding Competition Seaters are without question the finest bullet seaters I have ever used! The quality of construction and design is a ‘steal’! I am extremely impressed.

Fred Sinclair, Sinclair International

For ordering numbers on bushing style dies see chart on page 8 of downloadable catalogue.

Universal Decapping Dies

Decapping dies allow you to deprime and clean your cases prior to sizing.

The small decapping die will handle 22 thru 50 caliber cases with lengths up to 2.625”. An optional decapping rod for this die is designed to work with all 17 caliber cases and will accommodate the small .060” flash holes found on the BR and PPC cases.

For longer case lengths up to 3.0” use the large decapping die.

Note: the large die will not accommodate a neck diameter of less than 25 caliber.

Carbide Size Button Kits

Make inside neck sizing smoother and easier without lubrication. Now you can upgrade your die sets with a carbide size button kit. Available for bottleneck cartridges 20 thru 338 cal. The carbide size button is free floating on the decap rod allowing it to self-center in the case neck. See catalogue page 15 for available sizes and ordering numbers.

Special Small Base Body, Full Length & Type S – Full Length Dies

Now available in the following calibers for firearms with custom chambering that are tighter than SAAMI specifications.

Note: For the ultimate shoulder bump control, use these dies with our new Competition Shellholders.

Competition Shell holder Sets

Establish the perfect shoulder bump with no die adjustment!

You control the headspace. The easy to use Redding Competition Shell holders enable you to perfectly match the headspace of your reloaded ammo to any firearm. Once the proper Shell holder is determined your results are repeatable and no die adjustment is necessary. Each Shell holder has a distinct black oxide finish and is clearly marked to indicate the amount it will change case-to-chamber headspace – no special tools or gages are needed.

Packaged in five piece sets in .002” increments.

Full Length

Small Base Body

Tech Talk - Create The Perfect Shoulder Bump With A Simple Shell holder Change!

To maximise case life and the accuracy potential of your reloads, it is desirable to size fired cases the minimum amount that allows loaded cartridges to chamber freely.

Most hunters and many other shooters seeking smooth chambering reloads, full length size their cases each time. Since the interior dimensions of sizing dies are determined by the manufacturer, adjusting the shoulder setback is the only control a reloader has over how much a fired case is sized.

In the past, sizing die adjustment was made through the trial and error method of adjusting the die body in the reloading press. While acceptable results can be obtained using this method, precise adjustments were difficult at best. Using this method, firm contact with the Shell holder (squaring the die) was not always possible. As a result, irregularities in brass hardness and thickness, as well as the uniformity of case lube affected shoulder setback. The resulting headspace variations created can adversely affect accuracy.

To provide desirable Shell holder to die contact during sizing, with-out excessively setting the case shoulder back, Redding now produces Shell holders that are made in increments of .002” deeper than the industry standard. The nominal industry standard depth (dimension X) for Shell holders is .125”. The new Competition Shell holder Set includes five Shell holders that are deeper than this in increments of .002”. Therefore, the set includes shell-holders that are marked +.002, +.004, +.006, +.008 and +.010, which is the amount the shell- holder will increase base to shoulder case length and thus decrease shoulder set back and case to chamber head space.

To select the proper Shell holder for your particular firearm’s chamber, simply start with the Shell holder marked +.010. The Shell holder should be adjusted to make firm contact with the bottom of the sizing die during the case sizing operation. Resize a case and try it (unprimed and empty) in the chamber of your firearm. If the empty case does not chamber or chambers with difficulty, switch to the Shell holder marked +.008 and repeat the process. Stop at the Shell holder that allows the firearm’s action to close freely. Your cases are now being sized properly to fit your chamber with a minimum amount of head-space.

Neck Sizing Bushings

Redding Neck Sizing Bushings are available in two styles. Both share the same external dimensions (1/2" O.D. x 3/8" long) and freely interchange in all Redding Bushing Style Sizing Dies.

They are available in .001" size increments throughout the range of .185" thru .368", covering all calibers from .17 to .338 and clearly marked with size I.D.

By selecting the correct bushing, you are now able to provide just the right amount of neck tension to properly hold the bullet without excessive resizing.

Tech Talk - Bushing Selection and Use

The easiest way to determine the proper diameter bushing, is to measure the neck diameter of several loaded or dummy cartridges with an accurate micrometer. Subtract .001”–.002” from the average neck diameter and this diameter bushing will generally size case necks to create the proper press fit for the bullet.

Another method is to measure the neck thickness with a ball micrometer or our Case Neck Gauge (see page 33). Double the neck wall thickness and add this number to the bullet diameter. The result is the neck diameter of a loaded cartridge, and bushing size can be determined as above.

After loading several cases, it’s a good idea to test the neck’s grip on the bullet. The simplest method is to push the bullet in a loaded cartridge against the edge of your reloading bench with moderate hand pressure. The bullet should not move easily in the case neck. If the bullet pushes deeper in the case, select the next smaller bushing and start again.

When using your bushing die, we have found that lubricating case necks and installing the bushing numbers down may improve results. Many experienced reloaders like to adjust the die to size 1/2 to 3/4 of the case neck. This has been shown to improve accuracy in most instances.

Final note: If you are not sorting case neck wall thickness for uniformity, we do not recommend the use of any bushing style die without a sizing button.

DIE SPACER KIT

For use with combination die sets and all 7/8-14 reloading dies to quickly compensate for case

length or make a no crimp adjustment without the need to move the lock rings. Kit includes three spacers: No-crimp or partial resizing, 44 SPL/44 Mag spacer, 38 SPL/357 Mag spacer.

GRX Push-Trou Base Sizing Die

The G-Rx push thru Base Sizing Die is designed to restore fired cases from 40 S&W autoloading pistols that exhibit a bulge near the base.

By passing the case completely through the new G-Rx Die, the bulge is removed and the case may be returned to service.

The new G-Rx Carbide accomplishes the same task without the need for lubrication.

Optional Bottle adapter fits std. Powder & Shot bottles with 28-410 thread.

Instant Indicator – Headspace and Bullet Seating Depth Comparator

Designed for shooters seeking the utmost in accuracy from their handloads.

This instrument provides an extremely fast and accurate method for comparing the shoulder position of fired and/or sized cases and bullet seating depth uniformity. The addition of the “Range Adapter” makes this instrument more versatile and may now be used at the range or in the field without requiring the use of a reloading press.

Quickly perform any of the following tasks.

Check uniformity of shoulder bump

Check bullet seating depth uniformity

Compare sized cases to fired cases to determine the amount of headspace

Sort cases fired in two or more rifles

Sort sized cases for uniformity

Set up sizing die correctly

Check trim length uniformity

Sort bullets for uniformity

Now Supplied with the new “Range Adapter” for added versatility!

All Instant Indicators also include one bore diameter bushing, surface contactor, shoulder contactor, headspace gauge and complete instructions.

The “Instant Indicator” may be used on a family of cartridges with the same shoulder angle.

See cartridge availability and ordering numbers Note on page 19 of catalogue

Profile Crimp Dies

These handgun cartridge crimp dies were designed for those who want the best possible crimp.

Profile crimp dies provide a tighter, more uni-form roll type crimp, and requires the bullet to be seated to the correct depth in a previous operation. These dies are not for cartridges that headspace on the case mouth.

Rifle Trim Dies

Redding trim dies allow you to file trim your cases without unnecessary resizing. Other manufacturers use sizing die dimensions, forcing you to full length resize when trimming. For case forming and necking brass down from another caliber, Redding trim dies can be the perfect intermediate step before full length resizing. Pistol trim dies require extended shell-holders. Refer to die charts for available calibers and the extended shellholders required. See our case forming section on page 23.

Tap & carb Size Buttons

These long tapered expanders (size buttons) are made for expanding the necks of bottleneck cartridges up to the desired size.

Taper Crimp Dies

Designed for handgun cartridges which headspace on the case mouth where conventional roll crimping is undesirable. Also available for some revolver cartridges for those who prefer the uniformity of a taper crimp.

trim Dies

Redding trim dies allow you to file trim your cases without unnecessary resizing. Other manufacturers use sizing die dimensions, forcing you to full length resize when trimming. For case forming and necking brass down from another caliber, Redding trim dies can be the perfect intermediate step before full length resizing. Pistol trim dies require extended shell-holders. Refer to die charts for available calibers and the extended shellholders required.

Type S – Bushing Style Dies

Now anyone with a standard reloading press can benefit from advanced benchrest techniques.

The amount of resizing provided by conventional reloading dies has always been dictated by the manufacturing tolerances (SAAMI specifications) of the brass cartridge case itself. Reloading die manufacturers have been forced to design the neck diameter of their dies small enough to accommodate the thinnest possible brass.

This may be as much as .008" - .010" smaller than the maximum cartridge dimensions typically shown in most reloading manuals.

Since the majority of cases that the reloader is likely to encounter in the field are thicker than the minimum specifications that the dies were designed for, case necks are often resized excessively.

It can be easily demonstrated that excessive resizing of the cartridge case quickly leads to stress distortion and concentricity problems.

The new Type S - Bushing Style Dies offer a simple solution to this age old problem.

The Type S - Bushing Style Dies, Competition Seating and Neck Sizing Dies, Body Dies and our New Competition Shell holders are all products of Benchrest and 1000 yard Competition.

Type S – Neck Bushing Die

The new Type S - Bushing Style Neck Sizing Die provides reloaders with a simple means to precisely control case neck size and tension.

Uses interchangeable sizing bushings available in .001" increments.

The adjustable decapping rod allows positioning the bushing to resize only a portion of the neck length if desired.

Concentricity is enhanced by the ability of the resizing bushing to self centre on the case neck.

The decapping rod is supplied with a standard size button. This is especially useful for reloaders who are using commercial brass as is.

A decapping pin retainer is also supplied with most Type S - Bushing Dies except 17 and 20 Cal. This enables neck sizing without the use of the size button for those who sort and/or turn case necks for uniformity.

Carbide size button kits are also available for all Type S Dies. See page 15 for kit numbers by caliber.

Type S – Full Bushing Die

Full length resizing while maintaining exact control of the case neck is often desirable in one operation. The new Type S - Full Length Resizing/Bushing Die accomplishes this task with the precision you would expect from Redding.

Uses the same interchangeable bushings (.001" increments) as those used in our bushing style neck sizing dies.

The adjustable decapping rod allows you to adjust the bushing position, sizing only part of the neck length when desired.

Concentricity is enhanced by the ability of the bushing to self centre on the neck of the cartridge case.

All Type S (except 17 and 20 Cal.) dies are supplied with both the standard size button and a decapping pin retainer for the advantages and versatility described under our Type S - Bushing Style Neck Sizing Dies.

Note: By removing the bushing and all internal parts, the Type-S full bushing die may also be used as a body die.

Note: For the ultimate shoulder bump control, use these dies with our new Competition Shell holders. See page 18 for details.

All dies are supplied without bushings. For ordering numbers see pages 8 & 9 of the catalogue.

® Pro Shooting // All Rights Reserved. Website Design - EDGE